| Function: | Automatically completes filling, sealing, and packaging. |

| Application: | applicable for various types of premade pouches, flat bags, spout pouches, stand-up zipper pouches, and stand-up pouches |

| Material: | Powders, granules, liquids, and other materials. |

| Bag Width Range: | 50 to 300mm |

| Filling range: | 10 to 5000g |

| Packaging speed: | 40+ bags per minute |

This fully automatic packaging machine is designed for efficient and flexible modern production lines. It integrates bag removal, bag opening, fllng, sealing, and finished

product output. It seamlessly integrates with multi-head weighers, fillers,metal detectors, and carton sealers, allowing for rapid integration of complete packaging lines.

significantly improving production capacity and system collaboration.

Wide Range Compatibility: Supports bag with from 50-300mm and fill weights from 10-5000g, flexibly meeting diverse packaging specifications.

High-Speed and Efficient Operation: The mechanical drive is stable and reliable, processing over 40 bags per minute and boasting a service life exceeding 20 years.

Hygienic and Durable Construction: The entire machine is constructed of SUS304 stainless steel, meeting food safety standards, corrosion resistance, and easy cleaning.

Intelligent Control: Equipped with a 10-inch touchscreen, the machine features intuitive parameter settings and simple operation, reducing training costts.

Automated Maintenance: A built-in automatic oil supply system eilminates routine maintenance, and the entire unit is washable and equipped with an integrated water tank.

Compact and Mobile Design: The electriacl cabinet is located at the bottom, saving space and facilitating line layout adjustments and equipment relocation.

| Model | WH8-230R | WH8-300R |

| Working stations | Eight stations | Eight stations |

| Bag size | W: 80-230mm L: 100-400mm | W: 180-300mm L: 150-450mm |

| Bag type | Flat bag, stand-up bag, spout pouch, doypack etc | Flat bag, stand-up bag, spout pouch, doypack etc |

| Packing speed | ≤60 bags/min | 20-50bags/min |

| Filling range | 10-2500g | 100-5000g |

| Dimension | 2500x1460x2000mm | 2140x1830x1800mm |

| Weight | 1500 KGS | 2000 KGS |

| Voltage | According to requirement | According to requirement |

| Power | 4.5KW | 4.5KW |

| Air consumption | 0.6 m3/min | 0.6 m3/min |

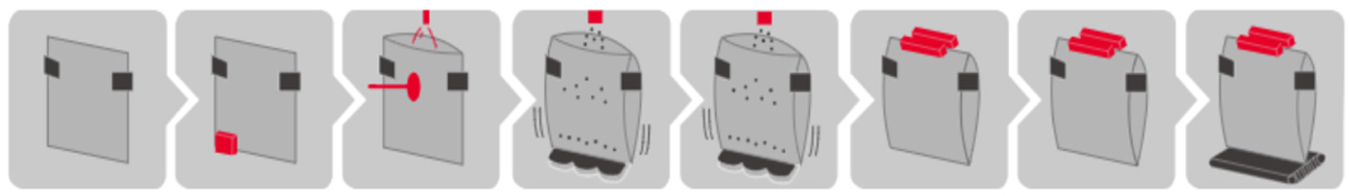

| Work flow: bag loading, coding, bag opening, bag struting, filling 1, heat seal 1, heat seal 2, output | ||

| PLC | Frequency converter | Touch screen | Solenoid valve | Bearing |

| Siemens | Siemens | Siemens | FESTO | IKO/IGUS |

Prefabricated bag packaging separates the bag-making and packaging processes. Bags are pre-made by specialized factories. The equipment only needs to perform operations such as bag removal, bag opening, packaging, and sealing, greatly streamlining on-site processes.

Date Coding — Non-contact inkjet printing (e.g., production date, expiry date, batch number) is applied to a specified area on the pouch. High-definition, permanent laser coding is available as an option.

Bag Opening — The pouch mouth is reliably opened before filling by high-pressure air jets or sophisticated mechanical fingers, preparing it for accurate filling.

Primary Filling — The primary metering system (e.g., auger filler, volumetric cup, liquid pump) performs the first precise filling of the product. Ideal for the main ingredient or large-volume filling.

Secondary Filling / Reserved Station — A flexible station. Can be equipped with a secondary metering system for adding supplements (e.g., sauce sachet, dehydrated vegetables) or reserved for functions like inspection or product settling, catering to complex recipes.

Flapping — Mechanical devices clean and flatten any product residue or curled edges from the pouch mouth before sealing, ensuring perfect and hermetic seals.

Sealing — The sealing station applies heat and pressure via precisely temperature-controlled sealing jaws (e.g., constant heat, impulse seal) to hermetically close the pouch mouth based on its material.

Seal Shaping — The freshly heat-sealed area is cooled and shaped under pressure to relieve stress, resulting in a flatter, stronger, and more aesthetically pleasing seal. This enhances seal reliability and product premiumness.

Here're some industires you can use in:

Solid -- Candy, Red dates, Oatmeal, Chocolate, Cookies, Peanut, Green soybeans, Rock candy.Pastry, Commodity. Puffed food, etc.

Granule -- Crystal MSG, Granule medicine, Capsule, Seeds, Raw Chemistry material, Sugar, Chicken essence, Melon seed, Nuts, Pesticides, Fertilizer, Feed, etc.

Liquid -- Detergent, Yellow rice wine, Soy sauce, Rice vinegar, Juice, Tomato paste, Peanut paste, Fruit paste, Chili sauce, Bean sauce, etc.

Powder -- Flavoring, MSG, Milk powder, Glucose, Washing powder, Raw chemistry material, White sugar, Pesticides, Fertilizers, etc.