| Function: | Automatically completes flling, sealing, and packaging. |

| Application: | applicable forvarious types of premade pouches, fat bags, spoutpouches, stand-up zipper pouches, and stand-up pouches |

| Material: | Powders, granules, liquids, and other materials. |

| Packing speed | 60~80 bags/min |

| Filling range | 10~1000 g |

| Pouch width | Max .170 mm |

This packaging machine uses a sturdy mechanical transmission structure and food-grade stainless steel 304/316 material, which is durable and stable, with a service life of more than 15 years. The equipment can pack more than 80 bags per minute, achieving double production capacity with a single machine, effectively saving production line space. Simple operation, support for convenient programming and friendly human-machine interface, easy to use and maintain daily.

| Model | WH8-170D |

| Working station | 8 stations x 2 lanes |

| Name | premade pouch double lane machine, double pouch packing machine |

| Bag size | W: 85-170mm L: 150-330mm |

| Packing speed | 60-80 20-50bags/min |

| Filling range | 10-1000g |

| Dimension | 2320mm x 2060mm x 1650mm |

| Weight | 3000 KGS |

| Power | 5.5kw |

| Air consumption | 0.4m2/min |

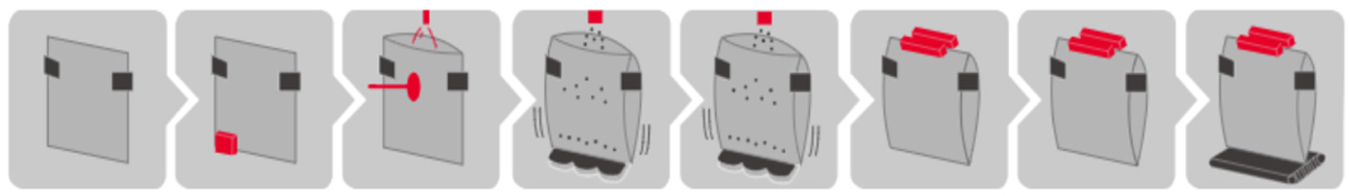

| Work flow: bag loading, coding, bag opening, bag struting, filling 1, heat seal 1, heat seal 2, output | |

| PLC | Frequency Converter | Touch Screen | Solenoid Valve | Bearing |

| Siemens | Siemens | Siemens | FESTO | IKO/IGUS |

This packaging machine offers exceptional flexibility and efficiency, handling bag widths ranging from 50 mm to 300 mm, fill volumes from 10 g to 5,000 g, and capable of high-speed packaging at speeds exceeding 40 bags per minute. The machine features a 10-inch touchscreen interface with an intuitive interface for easy operation, while the compact, floor-mounted electrical cabinet saves space and facilitates mobility. Furthermore, the machine supports flushing and maintenance, with a built-in water tank, making cleaning and maintenance easy and convenient.

Bag Picking — Precision vacuum suckers pick a single premade pouch from the magazine and transfer it to the rotary clamp.

Date Coding — Non-contact inkjet printing (e.g., production date, expiry date, batch number) is applied to a specified area on the pouch. High-definition, permanent laser coding is available as an option.

Bag Opening — The pouch mouth is reliably opened before filling by high-pressure air jets or sophisticated mechanical fingers, preparing it for accurate filling.

Primary Filling — The primary metering system (e.g., auger filler, volumetric cup, liquid pump) performs the first precise filling of the product. Ideal for the main ingredient or large-volume filling.

Secondary Filling / Reserved Station — A flexible station. Can be equipped with a secondary metering system for adding supplements (e.g., sauce sachet, dehydrated vegetables) or reserved for functions like inspection or product settling, catering to complex recipes.

Flapping — Mechanical devices clean and flatten any product residue or curled edges from the pouch mouth before sealing, ensuring perfect and hermetic seals.

Sealing — The sealing station applies heat and pressure via precisely temperature-controlled sealing jaws (e.g., constant heat, impulse seal) to hermetically close the pouch mouth based on its material.

Seal Shaping — The freshly heat-sealed area is cooled and shaped under pressure to relieve stress, resulting in a flatter, stronger, and more aesthetically pleasing seal. This enhances seal reliability and product premiumness.

This premade pouch packing machine is versatile and suitable for packaging a wide variety of materials:

Liquid Packaging: Ideal for liquids such as beverages, juices, detergents, shampoos, sauces, oils, and more.

Granule Packaging: Handles granules like nuts, dried fruits, snacks, coffee beans, and pet food.

Powder Packaging: Perfect for powders, including washing powder, milk powder, flour, cocoa powder, coffee powder, and spices.

Cooked Food Packaging: Also suitable for packaging cooked food, ready-made meals, and other food items, ensuring tight seals and durability for long-lasting preservation.